Our 2024 Guide to Automotive Software

Computer will Save Fuel on G.M.’s ’77 Toronado

That was the headline printed in a 1976 edition of The New York Times and marks the first time an onboard digital computer was used on a passenger vehicle. The second-generation Oldsmobile Toronado might not look like a revolutionary vehicle, but its electronic control of its spark plug was the first step in an age of computing in cars.

From something as simple as your windscreen wipers all the way to autonomous driving, you won’t find a vehicle today that doesn’t use some form of software. This means that every part of the car is more interconnected than ever and for EVs – just like for the Oldsmobile Toronado – it means that software can help improve performance,range, and critically emissions.

In today’s vehicles, software development can inform almost everything about a vehicle and it all starts with…

1. Requirements Capture & Systems Architecture

This is the earliest part of software development, where you analyse the wants, needs, and capabilities of the prospective systems that will exist in the car. In this process, the manufacturer will decide on a vehicle architecture for the suppliers they’ll be working with to build their systems within.

This is implemented at the vehicle level, where every individual part of the car, both separately and

together, needs to be considered. In the early stages of software integration, it will be almost impossible to get the exact desired outcome.

This is especially true if the engineers’ brief is unclear or not fully comprehensive in their requirements definition – by not establishing a coherent architecture early, system malfunctions become much more likely. In the early phases of vehicle system definition, it is most important to ensure that requirements are complete, coherent, and can be configured to relevant user requirements. Then the project can move on to System Engineering.

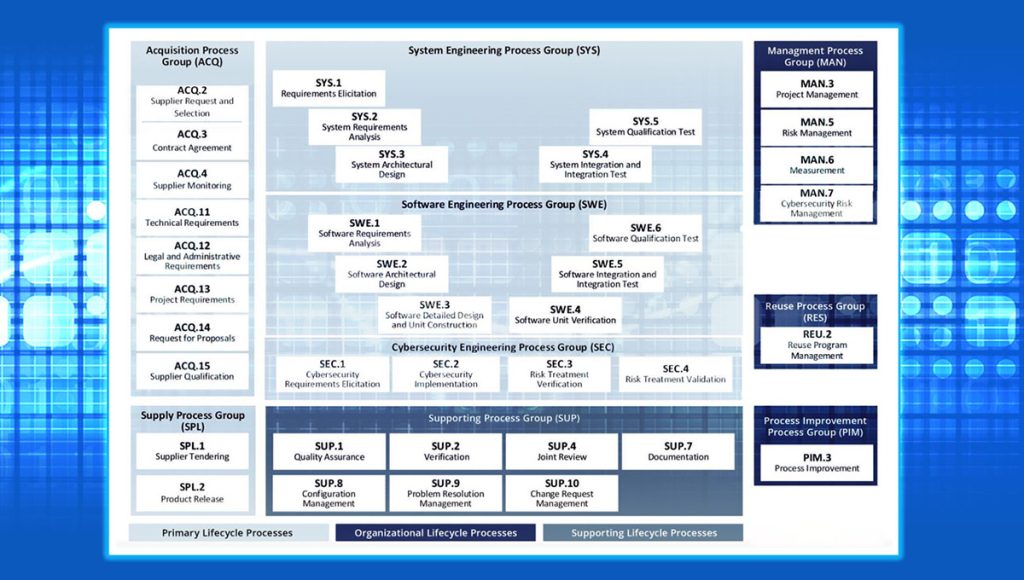

2. System Engineering

Once the system architecture is found at the vehicle level, whether using suppliers or not, the

systems are each developed separately, following that same vehicle architecture decided upon in the design phase. System Engineering requires the sourcing or development of the right hardware to manage each part of the system.

Today’s vehicles have highly complex functionality that can be distributed across many different controllers. The allocation of function and the definition of interfaces between those controllers is key to robust system engineering.

The more complicated the system, the more challenging this stage of development can become. For something like a windscreen wiper, the system development is simple – a motor to control the wiper and something to control the motor. But for a thermal system, for example, where there are more parts with more requirements, it will take a lot more work to get all these components working with each other.

With different systems requiring different standards, it can be common for the system engineering to take up a substantial amount of time in the development processes. Not to mention the required functional safety standards such as ISO 26262 and ASPICE, which can double or triple the time it takes to finish this process with the required level of robustness.

Even without considering FuSa standards, quality testing is a vital part of making sure these systems will work together to implement the requirements. At FutureMotiv, we make sure to include other engineers or departments in the quality testing process to avoid biases.

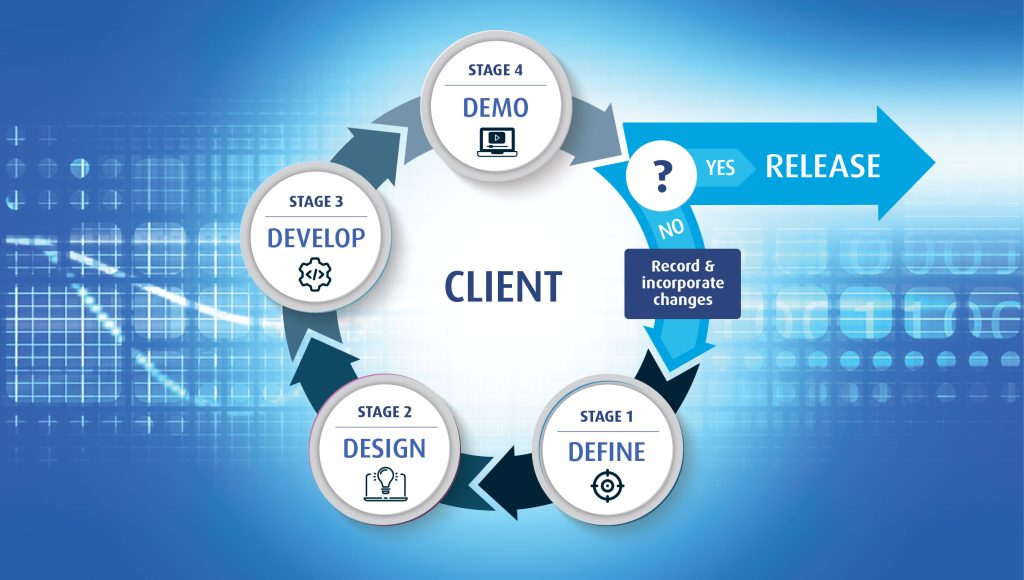

3. Software Controls

Once you have the system design in place, you can begin working on developing the software. This can take many different forms – and just as with system engineering, depending on the system requirements, this can range massively in terms of budget and time.

The huge growth in complex systems as the project develops means people and teams with a range of software skills needs to be brought together. This will include embedded controls development, Android development for infotainment systems or Linux development for off-vehicle telematics communications software.The central goal of the Software Controls stage is to deliver the functionality that was decided in the engineering stage. Testing can reveal potential issues which can impact delivering the initial specifications. For startups, this back and forth can be costly and when they’re looking to get projects moving quickly, we will implement an agile approach. The importance of getting things right the first time becomes critical.

Looking to progress a project quickly, this allows our clients the chance to source prototype parts together and secure further rounds of funding.

4. Testing

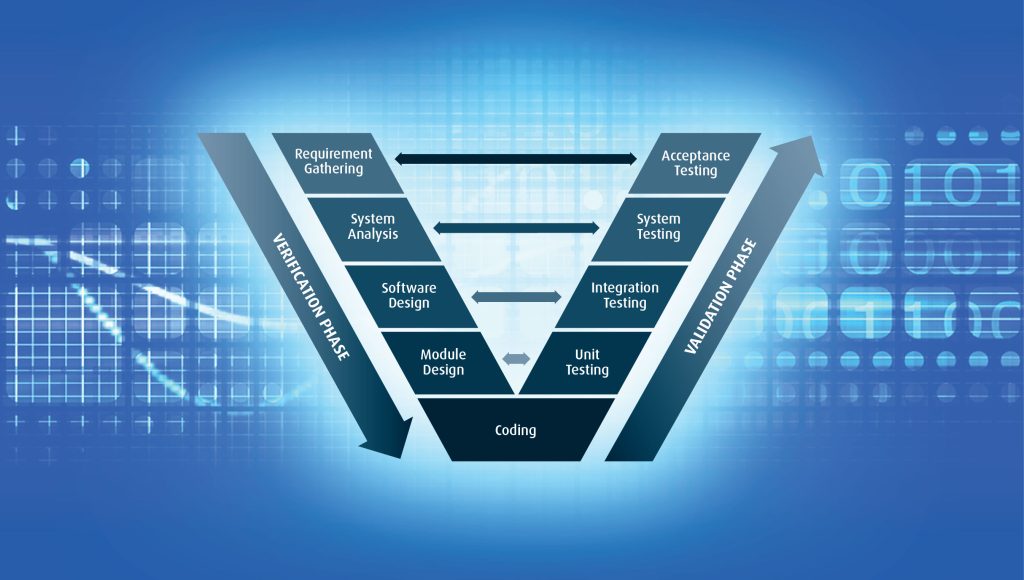

Software testing is the earliest part of the validation side of the V Cycle – and as vehicles are so reliant on having the right software to function, it’s vital to get the software to its best place.

Most testing exists in two states: virtual and physical.

Virtual testing involves creating a simulation of the entire car which is an incredibly complex and time-consuming process. It depends on timescale and budget, but a simulation of the vehicle is a great opportunity to test all parts – not just software – and though the short-term benefits might seem small, in the long term it makes processes much more efficient for those working on the project.

Physical testing involves creating a prototype made up of the hardware within the car that the software uses. This means suppliers can test the functions implemented in the Electronic Control Unit (ECU). This testing will initially be done on a test rig or lab car. Once the software passes these tests it is ready to go on a real vehicle.

During these tests, it’s likely that bugs will be discovered that previously went unnoticed. These bugs will often be small, but it’s important to fix them.

To test a project so that it meets industry standards will often involve other forms of testing, but to comply with functional safety standards, it has to be ensured that the software meets high- and low-level requirements. Often the challenge for startups is having access to people with the certifications, knowledge and space to perform these tests.

We recently wrote a guide on functional safety, why it’s so hard to implement, and the standards and regulations that must be adhered to – which you can read here.

Once testing is complete, the software is ready to be supplied to the project lead. Though, as we’ve all seen, software development is rarely finished even when a car hits the market. Regular updates and upgrades are to be expected – over the air software updates in vehicles is now common practice. Software is the beating heart of modern automotive, and it will continue to shape the way we drive for the foreseeable future. With the continued rise in automated driving and as more vehicle technology advances to support efficiency within batteries and systems, we’ll only continue to see software play an even more important role within automotive production.

At FutureMotiv, our software experts have been supporting startups and OEMs in both implementing software into their vehicles and creating entirely new software with unique capabilities for new BEVs, FCEVs, and vehicles ranging from electric motorcycles to HGVs.

We’d love the chance to discuss your next project. To get in touch, email info@rle-futuremotiv.com