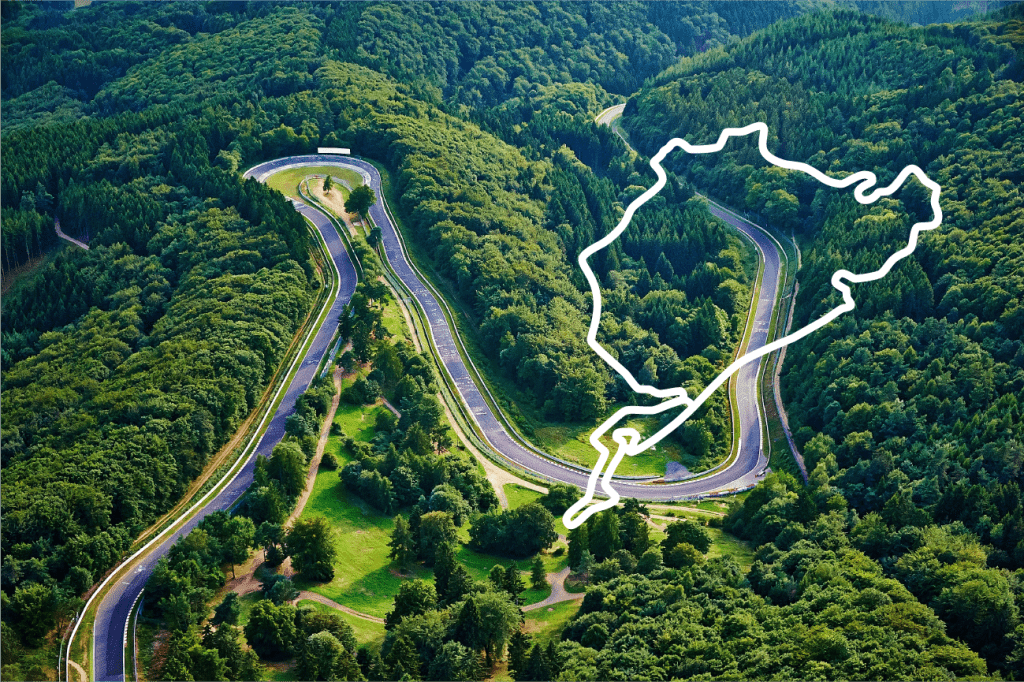

Case Study: A racy KERS-equipped hatchback fit for the Nürburgring

For this project we worked with one of the world’s most recognisable automotive brands on a new vehicle concept. Supporting the R&D arm of their business, we looked to answer a key question.

How do we make one of the world’s bestselling hatchbacks clean, yet powerful and fun to drive?

How would this be tested? Simple, really…

“They wanted to take it around the Nürburgring… We said give us a speed profile and we’ll come up with a battery that can provide the power to do that.”

Energy Storage and Power Distribution Engineer

Our role in this project was designing and assembling a Kinetic Energy Recovery System (KERS) battery and integrating this within the vehicle.

Given the unique nature of this project, our client didn’t have the internal resources required to deliver it and opted to work with FutureMotiv to bring this concept to life.

We kept the engine in the vehicle but added electric motors to the rear wheels, powering these by replacing the back seats with a battery.

“It was about seeing if we could make a 4-wheel drive hatchback, with an engine driving the front wheels and electric motors driving the back wheels and get some energy regeneration like you see in Formula 1.”

Our client provided us with the seat mounting points, plus the power and energy they needed. Our team figured out the rest.

This meant considering battery configuration, cell choice, and ultimately delivering the necessary power to complete a hot lap of the Nürburgring circuit that met their desired speed profile.

“There’s plenty of different cells available that have different power, size, energy.

You find a cell that will meet those requirements and then work out the optimum configuration for connecting them all together.”

During this process, we worked with suppliers to procure the necessary components and were able to assemble a working concept in rapid time.

“Six to eight months would be normal across the industry to complete a project like this.

We had the technical knowledge to do it and completed in four.”

With time to delivery representing one of the biggest challenges for this brief, finding the right suppliers was paramount to meeting deadlines.

“We put a lot of focus into finding suppliers that could deliver parts quickly.”

Speaking to our project lead about the key outcomes of this venture for FutureMotiv, they had this to say:

“We learned a lot about batteries during this process, and there really aren’t that many companies that can design and build batteries.

Now, when we’re working with other OEMs and start-ups, rather than just knowing a little bit about how you integrate a battery into a vehicle, we know everything.

We’ve built on our knowledge in this area from the ground up.”

There’s no doubt that briefs like this benefit the team, and our business as a whole, in better supporting future clients and projects.

“We can look at any Power Distribution Unit now and know exactly why everything looks the way that it does.”

Regarding the impact of a project like this on the industry or the world as a whole, one of the key challenges for future mobility will be transitioning to sustainable vehicles while retaining the enjoyment of the driving experience.

Mobility isn’t simply about getting from A to B, and conceptual projects like this help to inform OEMs and the industry on how to maintain a visceral, exciting driving experience in these changing times.

Concepts like these that set out to push the boundaries of performance absolutely have a role to play in designing and engineering mobility solutions for the future.

KERS batteries are now commonplace amongst London buses in the pursuit of more energy efficient and economical driving, marking just one amongst a host of other high-performance technologies being repurposed for mass market applications.

We look forward to working on more exciting concepts like this in the future.